limitation of vickers hardness test|vickers hardness testing machine diagram : distributor Every hardness test has its own advantages and limitations. In this article, the Vicker hardness test with its significance, applications, advantages and disadvantages, is discussed. Several factors are described here for a good understanding of the hardness test. Las traviesas de madera para exterior son elementos versátiles y robustos utilizados en paisajismo y construcción. Estas piezas de madera tratada resisten las inclemencias climáticas y el deterioro, lo que las hace ideales para su .Generally you should allow a full dental tray gap between each pouched load to help facilitate adequate drying of the pouches. The basic rule is if your autoclave takes five trays of unwrapped instruments then it will take .

{plog:ftitle_list}

Sterilization Standards FAQs. Below are the most common questions we receive about standards related to sterilization. View our general standards FAQs here.

Every hardness test has its own advantages and limitations. In this article, the Vicker hardness test with its significance, applications, advantages and disadvantages, is discussed. Several factors are described here for a good understanding of the hardness test.V. Limitations of Vickers Hardness Test. Despite all the benefits of the Vickers hardness test .

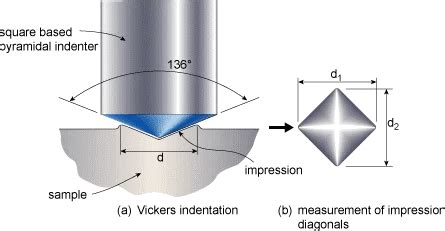

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.Every hardness test has its own advantages and limitations. In this article, the Vicker hardness test with its significance, applications, advantages and disadvantages, is discussed. Several factors are described here for a good understanding of the hardness test.The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials to Vickers and Knoop). There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over other metallurgical hardness tests.Most Vickers and Knoop testers are very accurate in applying the test force, as well as measuring distance. However, when most people think of microhardness testing, three terms often come into their mind: finicky, subjective, and time consuming.

In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to overcome the problem of cracking in brittle materials. One limitation of the Vickers test is its speed. Most international test methods limit how fast the test can be performed so that repeatable results are obtained. Also, some kind of surface preparation is typically required so that the diagonal lengths required to calculate the area are clearly visible.V. Limitations of Vickers Hardness Test. Despite all the benefits of the Vickers hardness test method, it has a few drawbacks as well. Some of these drawbacks include that whenever a sample material surface is precoated, the coating thickness may affect the accuracy of .

The Vickers Hardness test measures the indentation hardness for small parts or thin sections of metals, ceramics, and composites – almost any type of material in fact.

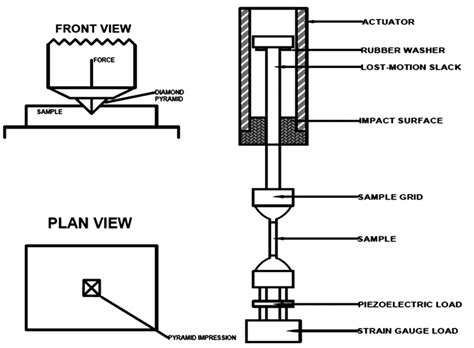

vickers hardness testing machine diagram

Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .Every hardness test has its own advantages and limitations. In this article, the Vicker hardness test with its significance, applications, advantages and disadvantages, is discussed. Several factors are described here for a good understanding of the hardness test.The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials to Vickers and Knoop).

There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over other metallurgical hardness tests.Most Vickers and Knoop testers are very accurate in applying the test force, as well as measuring distance. However, when most people think of microhardness testing, three terms often come into their mind: finicky, subjective, and time consuming.

In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to overcome the problem of cracking in brittle materials.

One limitation of the Vickers test is its speed. Most international test methods limit how fast the test can be performed so that repeatable results are obtained. Also, some kind of surface preparation is typically required so that the diagonal lengths required to calculate the area are clearly visible.V. Limitations of Vickers Hardness Test. Despite all the benefits of the Vickers hardness test method, it has a few drawbacks as well. Some of these drawbacks include that whenever a sample material surface is precoated, the coating thickness may affect the accuracy of .The Vickers Hardness test measures the indentation hardness for small parts or thin sections of metals, ceramics, and composites – almost any type of material in fact.

vickers hardness test procedure pdf

Since biohazard bags inside of an autoclave often contain latex or vinyl safety gloves as well as paper and plastic culture plates, some melting should be observed with respect to these items.

limitation of vickers hardness test|vickers hardness testing machine diagram